Conveyor BeltSince we produced the first conveyor belt in Korea, we have supplied conveyor belts of excellent quality to various industrial sites to help them maximize the efficiency of materials transportation and flow of logistics. |

|

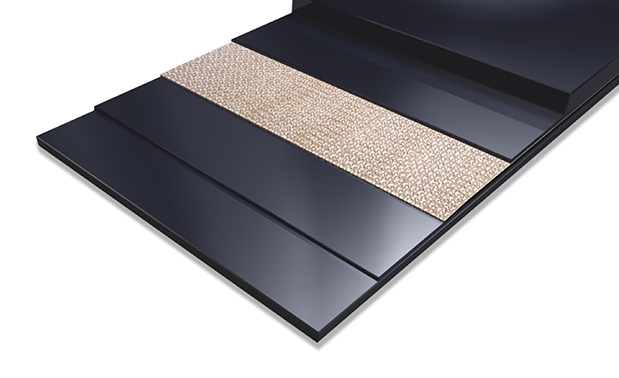

Multi-Ply Conveyor Belt Depending on Usage, a core made of nylon or polyester is selected, and the number of plies is determined according to the required strength. It is used in combination with various kinds of cover rubber. |

|

|

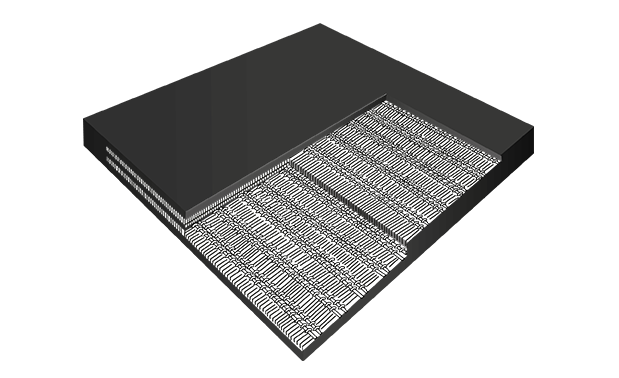

Mono-Ply Conveyor Belt As a single layer of solid woven core is applied, it has small elongation and excellent impact resistance. |

|

|

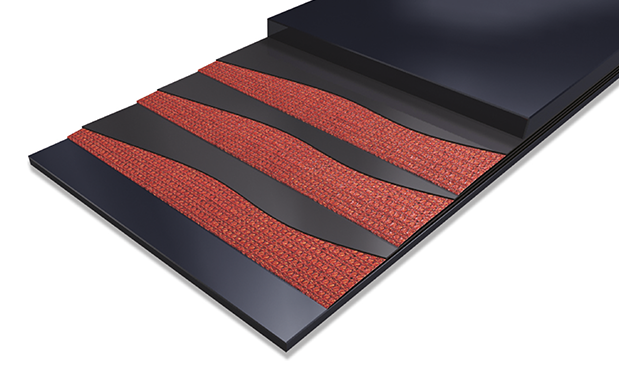

Less Ply Conveyor Belt As two layers of straight warp core is applied, it has excellent flexibility and impact resistance. |

|

|

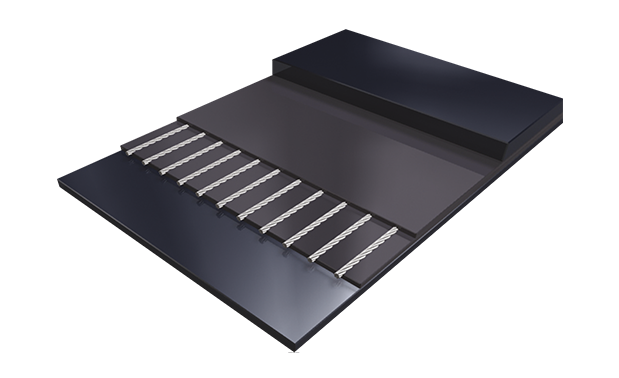

Steel Cord Conveyor Belt As a high carbon steel cord is used, it has excellent flexibility for its strength, and it minimizes the take-up distance as it has very low elongation 1/10 of a general cover belt. |

|

|

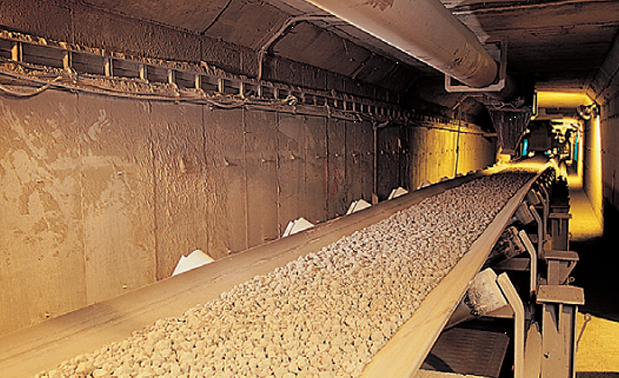

Abrasion Resistant Conveyor Belt Due to the characteristics of conveyed materials, it is applied to a line requiring abrasion resistance, and as the life of the belt has been extended, it reduces maintenance cost. It is mostly used in mines and quarries. |

|

|

Heat Resistant Conveyor Belt It is used to convey materials above 60¡É. In particular, the highly heat-resistant HRP belt shows best performance in conveying hot materials. |

|

|

Rip Protection Steel Conveyor Belt As steel cords or fiber cords are inserted transversely, it reduces the spread of the lengthwise damages to the belt, and provides excellent impact resistance. |

|

|

Chemical Resistant Conveyor Belt Depending on the characteristics of the conveyed materials, acid-proof or alkali-proof cover rubber should be selected. It is used to convey materials like chemicals, foods and fertilizers. |

|

|

Fire Resistant Conveyor Belt It reduces damages to the belt and the line in case of fire. It is mainly used in the granaries, fertilizer factories, thermal power plants and coal mines. |

|

Oil Resistant Conveyor Belt It prevents the swelling phenomenon, cover rubber flaking phenomenon, and reverse trough phenomenon that are occurring when oil-containing materials are conveyed. |

|

Anti-Static Conveyor Belt It is used if there is a risk of adhesion or explosion of the conveyed materials due to electrostatic discharge (sites where electronic products are handled with dust). |

|

Color Conveyor Belt It is mostly used to convey colored materials that must avoid contamination by the black cover rubber, and makes it easy to sort the conveyed materials. |

|

Impact/Cut Resistant Conveyor Belt The reinforcing steel cord inserted in the widthwise direction of the belt minimizes damaged to the belt core due to sharp objects or strong impact, and prevents the damaged portion of the belt from spreading and breaking. |

|

Hybrid Conveyor Belt The flexibility of a nylon(NN) belt and the advantage of low elongation of a polyester(EP) belt are combined in this belt. By applying it to the line with belt elongation problem when take-up distance is not secured, belt maintenance cost can be reduced. |

|

Clean Face Conveyor Belt The clean face conveyor belt is an environmentally friendly product designed to maximize the performance of a belt cleaner. It minimizes adherence of conveyance remnants on the surface of the conveyor belt and reduces the piling up of conveyance remnants that were not removed by the cleaner in the return part, which ensures the convenience of conveyor belt line management. |

|

Energy Saving Conveyor Belt The energy saving conveyor belt reduces motor power consumption by minimizing the resistance between the cover rubber and the idler. |

|

|

Bucket Elevator Conveyor Belt This conveyor belt is suitable for vertical conveyance. As it uses high-strength steel cord or polyester core, it prevents damages to the belt due to the bucket and weight of the conveyed material. As the take-up length is minimized, it reduces the footprint. |

|

|

Concenter Conveyor Belt As it has grooves at a given interval, it is effective in conveying materials at an angle. Powdered materials or particles can be conveyed at a slope of 17¢ª ~ 28¢ª and bags and packages can be conveyed a slope of 30¢ª ~ 35¢ª. |

|

|

Corrugated Sidewall Conveyor Belt By corrugating the surface of the belt, the sectional area of load and the carrying capacity increase and minimize the conveyor width. By attaching fin corrugation in the direction of belt width, steep and vertical conveyance is possible, minimizing the footprint. |

|

|

Pipe Conveyor Belt Since materials are conveyed in a closed system, dust and foreign objects can be prevented. With the maximum angle of inclination of 30¢ª, steep conveyance is possible. Unlike an ordinary conveyor line, three-dimensional layout in all directions is possible, and the footprint is minimized. |

|

|

Return Pipe Conveyor Belt As the carrier side, has a trough-type structure, and the return side has a pipe-type structure, it minimizes contamination of the lines due to the dust on the return side. |

|

Rough Top Conveyor Belt The rubber surface cover of the conveyor belt is made in a shape of bosses to prevent the conveyed materials from slipping. It is suitable for conveying plywood and packaged articles with less frictional force. |

DRB America : TEL. +1-714-739-2922 (Toll Free : +1-888-860-4450), FAX. +1-714-739-2925